Since 1989, A tier 1 supplier of injection molded and thermoformed parts

Honored by Mitsubishi as a zero-defect supplier

A proud supplier For Companies including

Capabilities

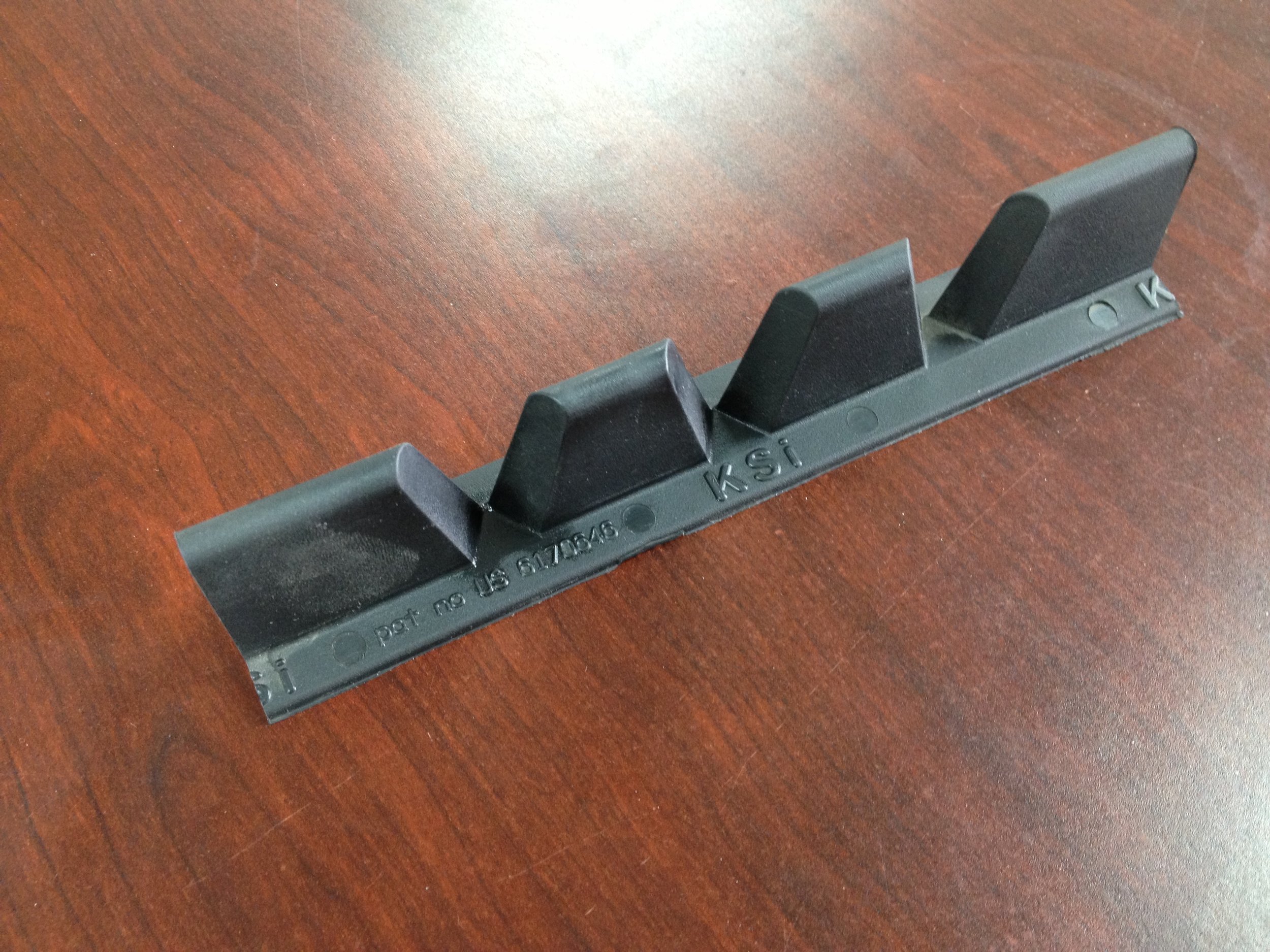

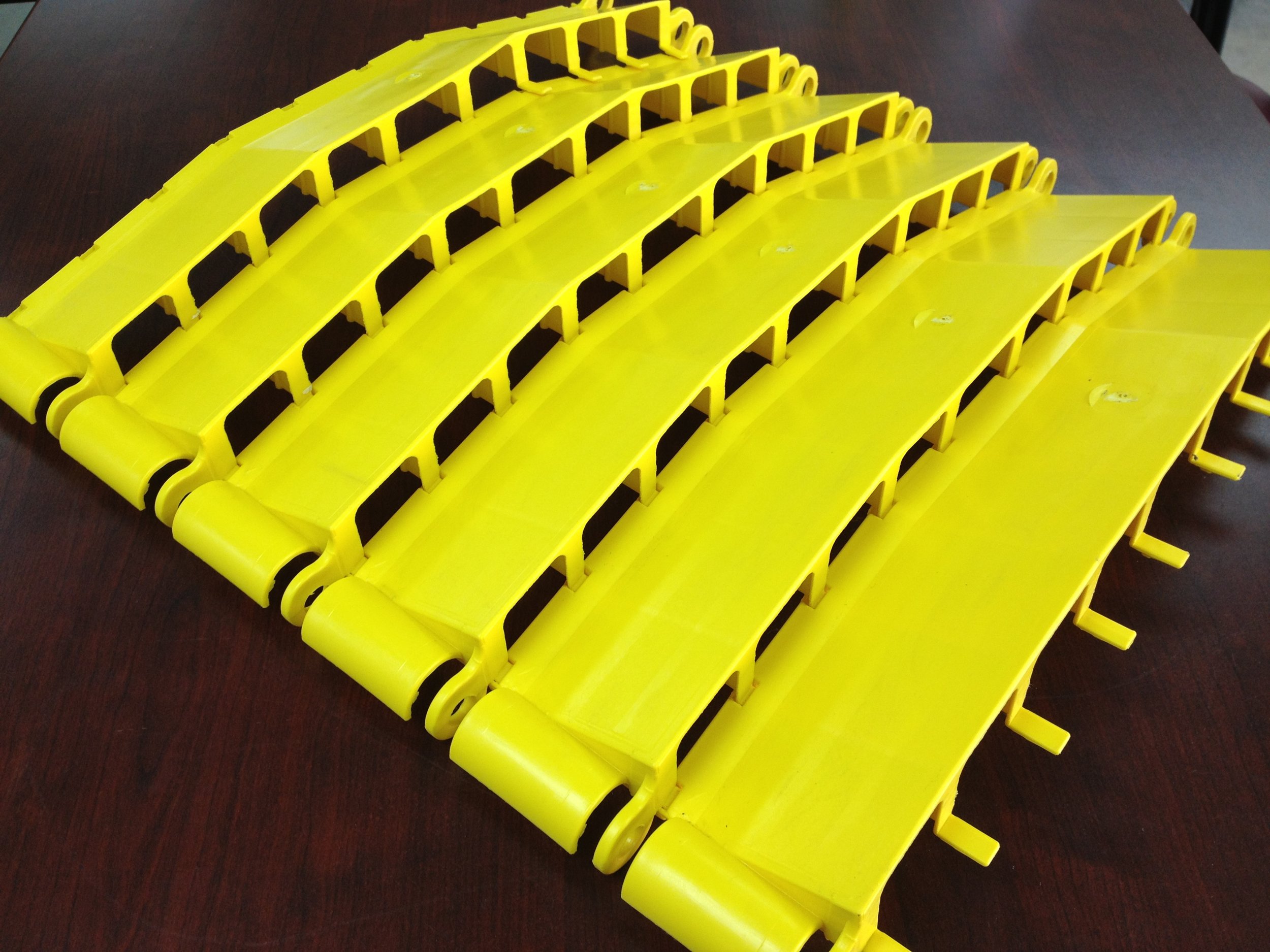

Injection Molding

PDI delivers top quality injection molded parts that match your specifications. Contact us to see if we can put one of our 11 injection molding presses to use making your parts.

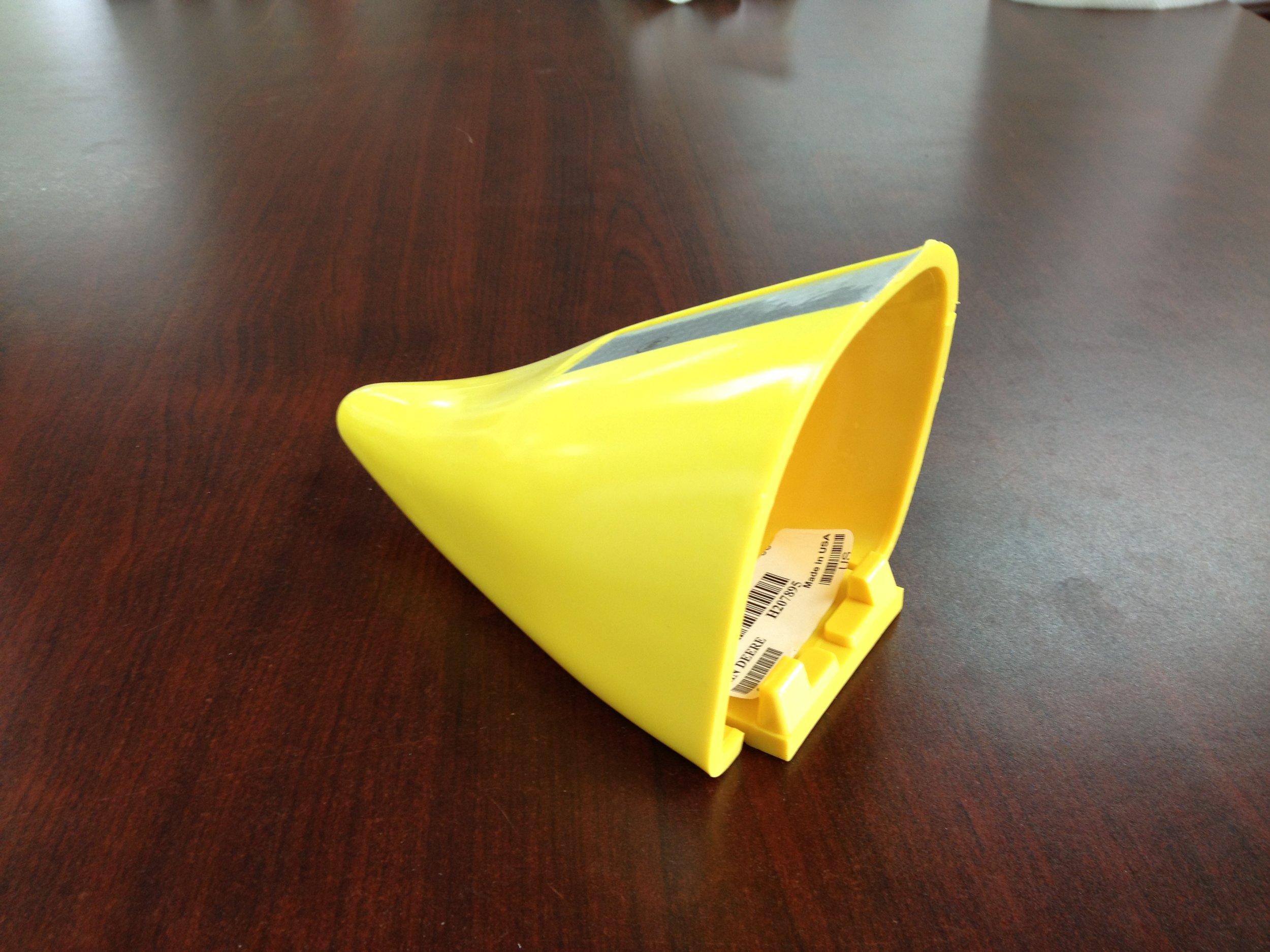

Thermoforming

For more than 2 decades, PDI has led the way with thermoforming. This economical process can make thin plastic parts on a tool that costs a fraction of what a comparable injection mold would cost.

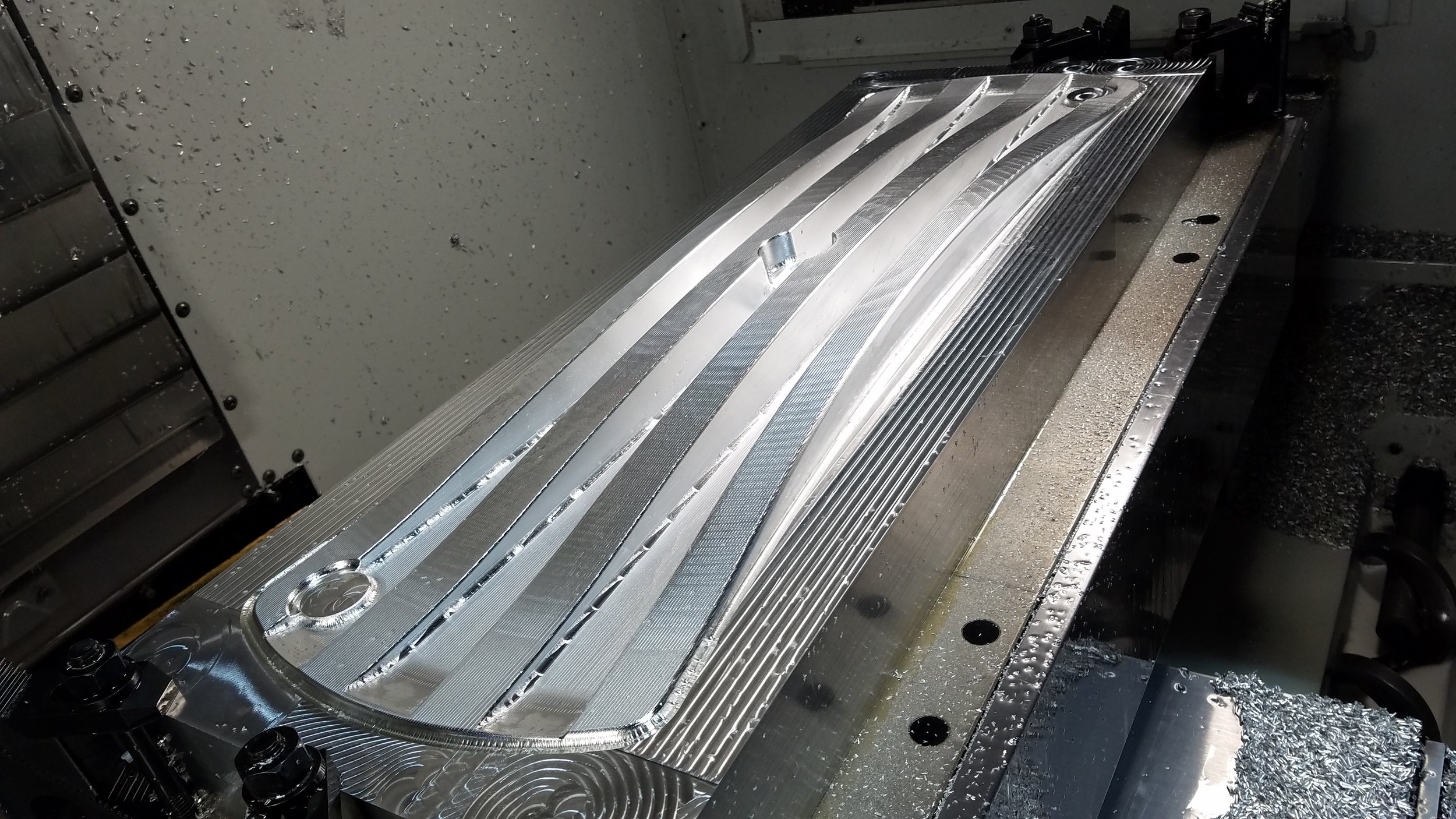

Tooling & Part Design

Our engineers are skilled in injection molded part design and mold design. No matter where you are in the development process we can help you get from concept to full-scale production.

Customer Testimonials

“At Agri Drain Corp we have worked with PDI and their engineering department on a number of projects. They have been and continue to be a valuable partner in the design and development of new products. PDI also produces injection molded parts for our company. They are quality conscious, responsive to our requests and competitive in their pricing for the services and product they provide.”

-Chris, Agri Drain Corp

“PDI has been molding shims for us for more than 10 years, and they have always delivered on time at a competitive price. The new products that we developed in tandem with their engineers have been instrumental to our growth as a company.”

-Kristy, Glazelock, Inc.

OUR PROCESS

Learn how we can get you from concept to full scale production

Step 1: Design Your Part

It all starts with a drawing. Submit whatever you have: 3D models, 2D models, or a sketch on the back of a napkin. Our engineers will work with you to make your design applicable for injection molding or thermoforming. If you don't have a design created, contact us, and allow us to help you through the design process. Depending on your needs, we can provide as much or as little design assistance as needed.

Step 2: Request a Quote

To get started with your quote, please Email us the following:

2D Part Drawings (.pdf, dxf, dwg...)

3D Part files (.stp, .igs, .x_t, .sldprt, we run the latest version of SolidWorks and we can open most files)

Estimated annual ordering quantities

Within two or three business days, we'll provide a quote for tooling and part productions. Depending on your needs and sourcing preferences, we may build the tool in-house or with one of our three tool building partners. We may also source your tooling from one of our overseas partners to reduce costs. Regardless of where your tool is built, we will always produce your parts in-house in our factory in the United States.

Step 3: Submit a P.O.

Upon receiving your order, we'll get started working:

First, we'll build a new injection mold or thermoforming tool for you. You don't have to think about the design of your tooling, our engineers take care of it all.

Once the tool is complete, we'll work with your engineers to establish quality standards. Every production lot is inspected before it leaves our factory to guarantee quality for our customers.

Lastly, after establishing quality standards, we're ready to make your parts. We’ll produce any quantity you request for each order that you place with us.

Let's get started